The Model Car is Born

When Herpa presented the first model cars perfectly in one of the model railroad scales at the Nuremberg toy fair in 1978, it was a sensation on the scene. Thanks to the great attention to detail they displayed, the models were seen not only as model railroad accessories, but as collector items, right from the beginning.

The first three truck models from 1980.

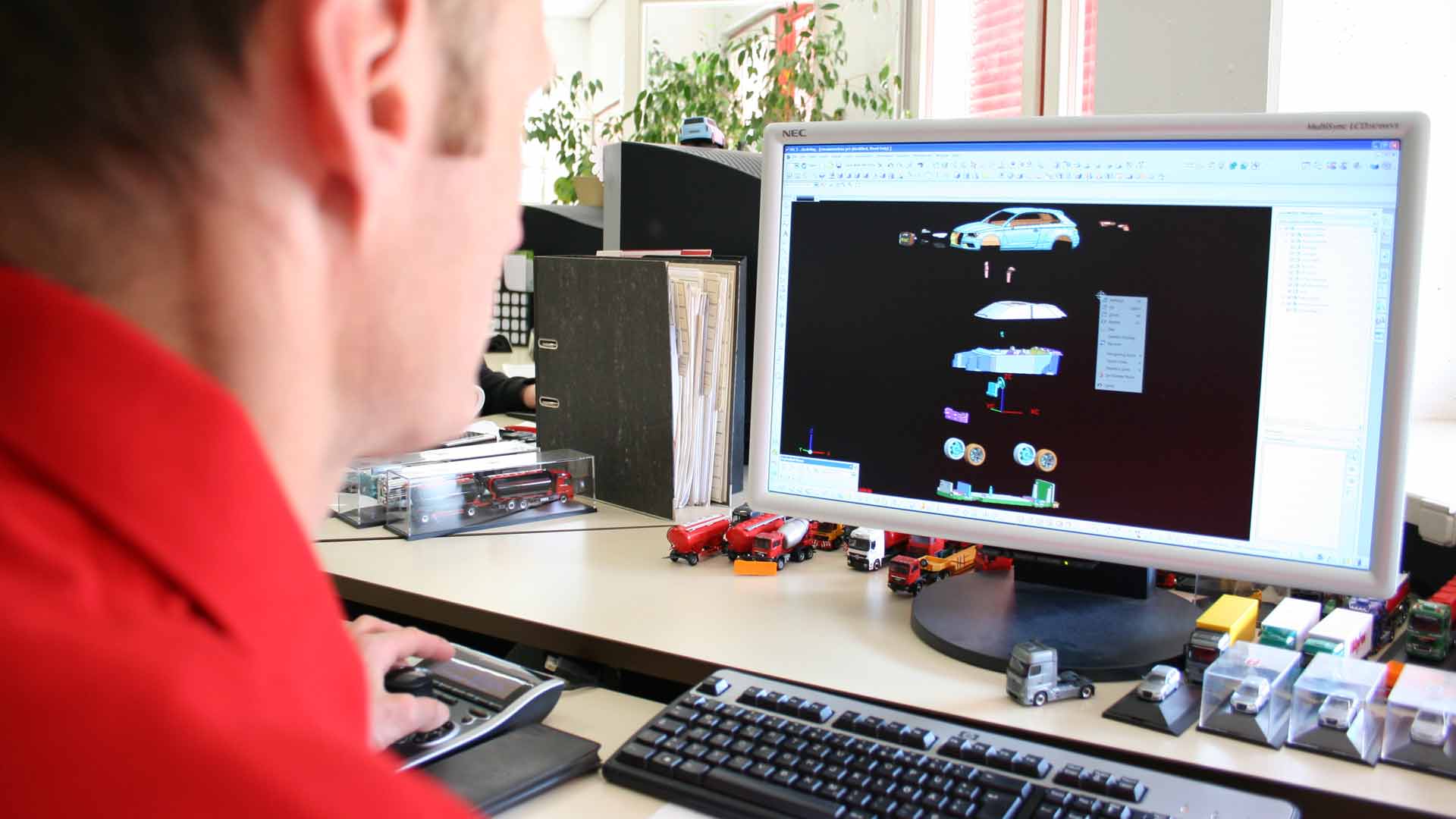

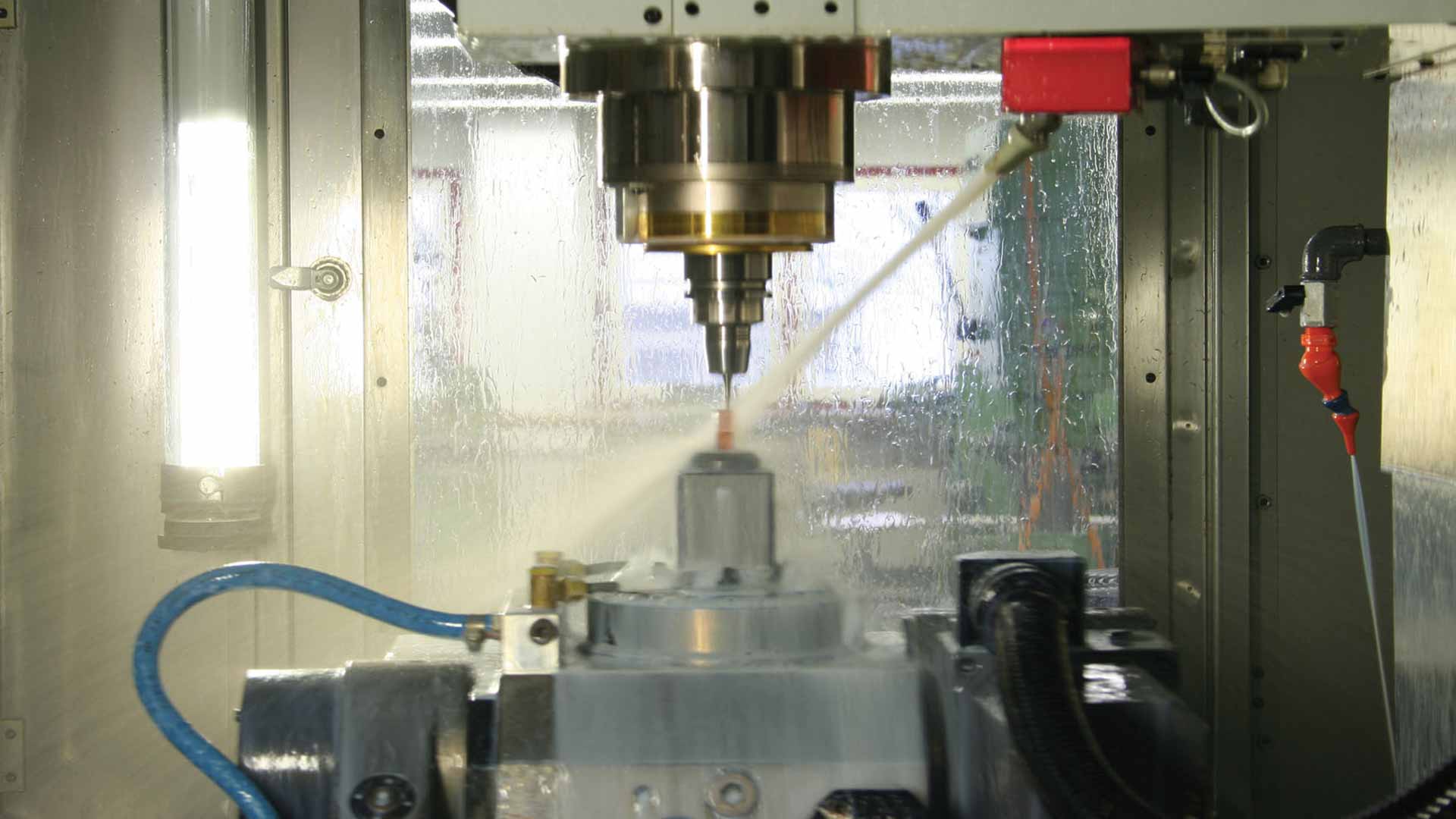

In the 1970s, there were almost no model vehicles in the 1:87 scale, so in 1976 the idea was born to offer these high-quality accessories for model railroads. Just two years later, the first five car models were presented at the toy fair in Nuremberg and were an immediate success, followed by the first three truck models in 1980. Right from the start, Herpa focused on quality and attention to detail. Exterior mirrors were "molded on", and windshield wipers and interior rear-view mirrors engraved into the windshield. This created two new departments at Herpa: Construction and Mold Making. Herpa constructed models and its own molds. Initially, wooden molds were elaborately produced in the 1:10 scale, and the injection molds for the models in 1:87 were created by copy milling machine. Incidentally, the first six wooden models were sourced from Schuco at low cost, after which Herpa created its own. From 1988, Herpa usually received the original data from the vehicle industry, and since then the models have been produced in even greater detail using CAD technology. While the first trucks had around 15 parts, today they consist of over 40. "Herpa has set new standards in many respects," explains Product Manager Stefan Blank. "For the first time, there are models in metallic paintwork, the vehicles being elaborately printed and not just covered in stickers. Thanks to embossing technology, the model’s radiator grille and other chrome parts are actually chrome-plated."

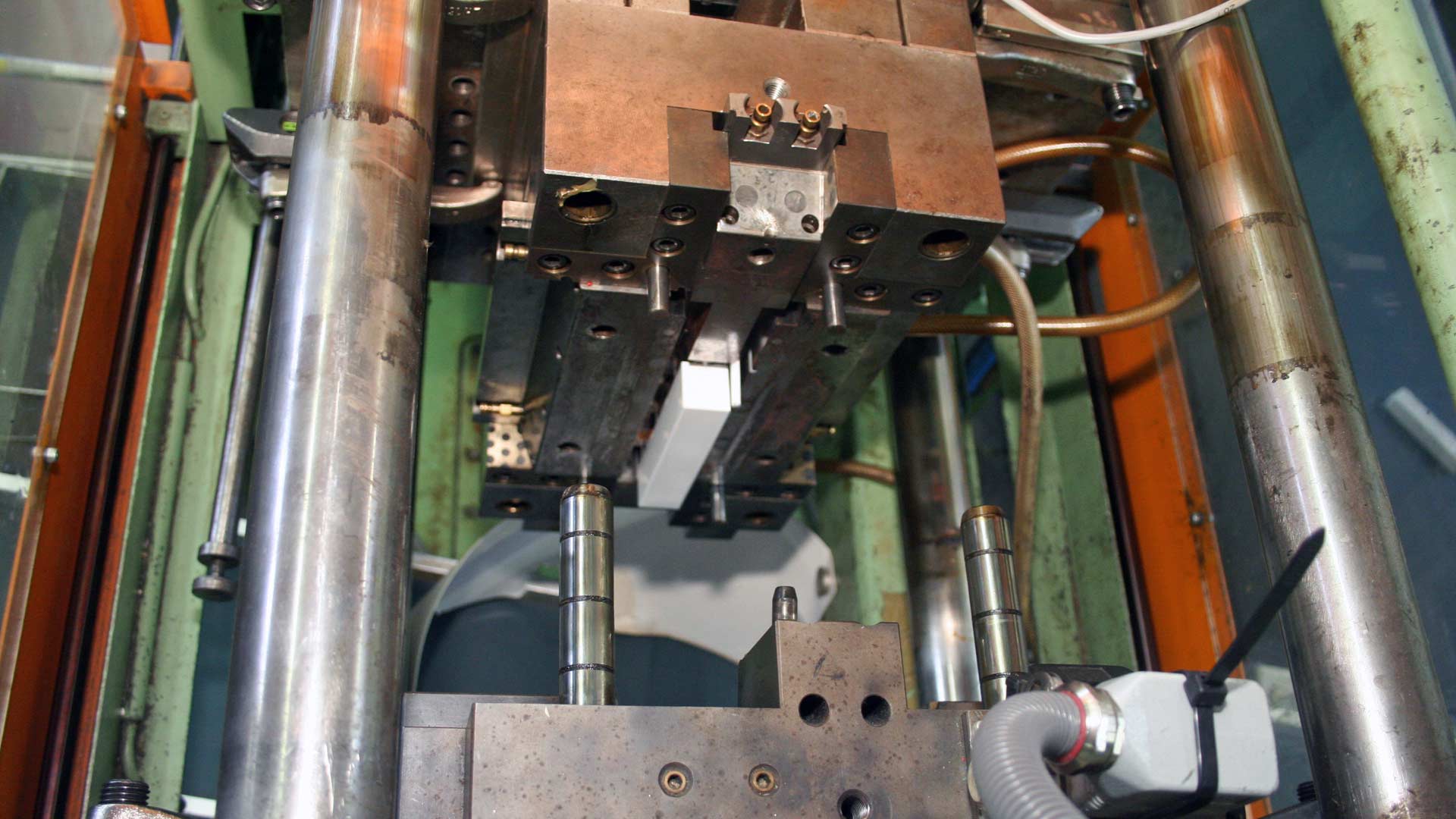

A model is created: construction, mold making and embossing.

It's the shape that counts

After the first five models, the molds were designed in such a way that the models did not have to be ultrasonically welded, but rather plugged together. Although this was more expensive than gluing, it meant that model builders could easily take them apart for repainting. And by cleverly designing the molds with different inserts, different variants of individual vehicles were able to be produced more economically as models. In the original, there were easily 14 or more variants of a given truck tractor. Herpa did not realize all of them, but significantly more than the competition.

After the mold is injected, it is meticulously checked.

The first show trucks

Together with airbrush artists, Herpa also repeatedly realized original show trucks, of which, of course, models were provided. Peter Littger designed an airbrushed truck with a BMW, a computer, and an airplane as motifs. "That was basically Herpa's first show truck," says former product manager Matthias Wolff. "This led to the idea of creating a truck with the airbrush artist Walter Rosner. That was how the monument truck was created." A total of 43 gnomes can be seen on this truck, two of them on the tractor unit representing the managing directors of the time, Claus and Dieter Wagener. The "History of Mankind" series of Rosner motifs was subsequently created. There were a total of 15 different trucks on topics such as the Crusades, the Gold Rush, the Vikings, the world's oceans, and space travel. The third truck, "The Seven Wonders of the World", even appeared three times after the tractor unit was swapped in the original. The models were designed so elaborately that they would no longer be feasible today, making the models of that time very valuable today.

[1] The first "airbrush truck" from 2001.

[2] Former product manager Matthias Wolff in the Herpa product archive with the monument truck.

[3] The first Herpa show truck...

[4] ... and from the other side

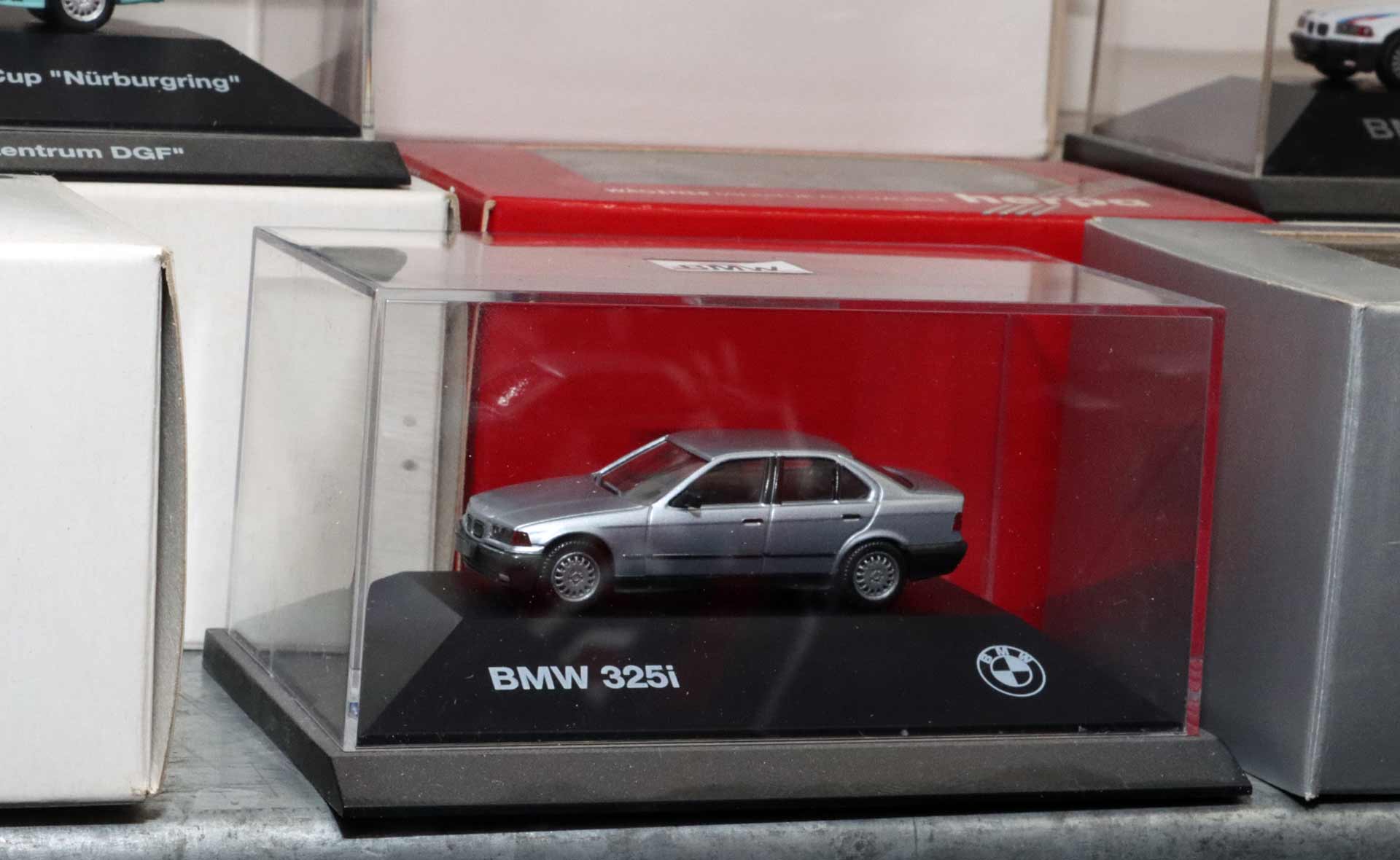

The second mainstay: industrial models

From the very beginning, orders from the automotive industry have been an important basis for production at Herpa. All major car companies ordered models of their vehicles, which were initially given away - and later sold. The industry often ordered 20,000 to 30,000 units - a total of 180,000 models of the E36 BMW 3 Series being delivered to BMW and specialist dealers - 12,000 units being delivered on the first day alone. In the 1990s, there were 32,000 units of some car models - 8,000 in each color. With these large quantities, the costs for molds and construction were easier to absorb. Today, these are in the six-figure range for a truck model and in the high five-figure range for a car.

The BMW 3 Series, E36 series

Fewer and fewer car models

In the early years, the industry was grateful to have original vehicles reproduced as models. At that time, licenses were not required, but today it is no longer possible without them - Herpa only produces models with permission. In many cases, these are no longer available from the automotive industry, which is often represented by licensing agencies that naturally seek to generate as much money as possible. What’s more, from 2007 onwards, all the major car brands withdrew from the 1:87 scale and opted instead for 1:43 or 1:18. Today, many OEMs are foregoing sales of model cars altogether. As frightening as it sounds, this is often due to the company's own bureaucracy. This will make it increasingly difficult to realize car models at a reasonable cost in the future. Models will only remain affordable in large numbers, for example through different variants such as emergency vehicles or cabs. This means that a BMW 6 Series, for example, no longer stands any chance to appear as a model, just like many every-day or small cars. Moreover, many original vehicles get a facelift after just a couple of years, which means that the lifespan of a model is reduced.

The first high-tech construction machines

Another mainstay for Herpa are the so-called forwarding models. The first orders for these came from dealers wishing to sell vehicles from their own region. Today, it is the forwarding companies themselves who order models of originals in their fleets. In 2001, Liebherr sought to realize a wheel loader model in cooperation with Herpa. It became the first highlight in the construction sector. Bulldozer, asphalt milling machine, and truck-mounted crane - many more machines followed.

About 400 models a year

Today, 60-70 new models are released six times a year. Incidentally, the best-selling car model is one of the very first: the Citroen 2CV with well over ½ a million units in a wide range of variations. The Trabant also appeared in many variations in a very large edition. Meanwhile, the so-called "Sun Caravan" has been the largest single order. This was a pack of three light blue Mercedes vans. 300,000 units were dispatched in 1984 within just two weeks.

[1] The most produced model - the 2CV.

[2] Initially, ten models were always delivered to dealers in blister packs like this.

[3-4] The Trabant also appeared in a large edition.

[5] The so-called "Sun Caravan" with three Mercedes vans from 1984 has been the largest single order.

The end of bushes and trees

The production of the former Herpa products for landscaping, such as grass mats and scatter material, was relocated to Hong Kong in 1983. The new production facility was located on the 11th floor of a high-rise building. To get the machines up there, a section of wall was removed without further ado. The German-made machines were then hoisted up to the 11th floor using a mobile crane. This product line was finally shut down in 1988. Meanwhile, the last photo articles were produced in Dietenhofen up to 1996, before this division was also discontinued. Since then, Herpa has concentrated solely on the production of model vehicles.